The commercial ice machine market is hot. Whether it is driven by growing demand for cold rather than hot drinks, or by rising global temperatures, or a host of other factors is hard to say, but the need for ice in foodservice outlets is only going to increase.

According to the latest report from MarketWatch, the value of the commercial ice machine market in 2021 was $1,295.2m and is set to reach $1,896.9m by 2028, growing at a CAGR of 5.6%. That presents a huge market opportunity for leading manufacturers such as Hoshizaki, Manitowoc, Scotsman, and Ice-O-Matic.

The ability to capitalize on that rising demand will, however, depend on how well those manufacturers can innovate to address the concerns of operators in two key areas: hygiene and sustainability.

Making ice is a fairly simple concept – freeze water – but behind that process there are a host of factors that operators must consider. From the customer perspective, the most important is the growing preference for different kinds of ice, particularly in the gourmet market, where shaped or flaked ice can be an important differentiator. From the operator’s perspective, however, cleanliness and energy efficiency are becoming the main priorities.

“It might sound obvious but the number one thing operators want is a continual supply of ice without interruption,” says Scott Bingham, director of marketing (foodservice and workplace) at Follett Ice. “They want to never have to think about ice, knowing it will always be there. That is a foundational need.

“Energy efficiency has been driven over the past few years by the US Department of Energy creating a new minimum Energy Star standard to sell a machine, so manufacturers are reacting to that,” he adds. “Then there are also refrigerant regulations – the UK and European Union are ahead of the US in terms of more stringent requirements. Sanitation and hygiene have also become more important, though not necessarily due to regulation.”

Covid drives cleanliness

The focus on hygiene has come not through regulatory pressure but in response to the way the Covid-19 pandemic has changed customer expectations and increased awareness that cleanliness is a key factor in preventing the spread of infection.

“All manufacturers have made innovations and improvements, but tackling the mould potential by various methods is a huge positive move,” says Brett Daniel FCSI of US consultancy Camacho Associates.

“Nobody cleans their ice machines like they’re recommended to do, so to be able to combat that from the manufacturing side is a benefit to everyone using that ice. I think there will be more development to enable sanitizing and keeping the machines clean without an operator’s input.”

Alexander Hofer FCSI, CEO and senior consultant at H44Team, an independent planning bureau for the professional catering sector, agrees that hygiene should be a top priority, but sees a patchy response from manufacturers when it comes to addressing the issue.

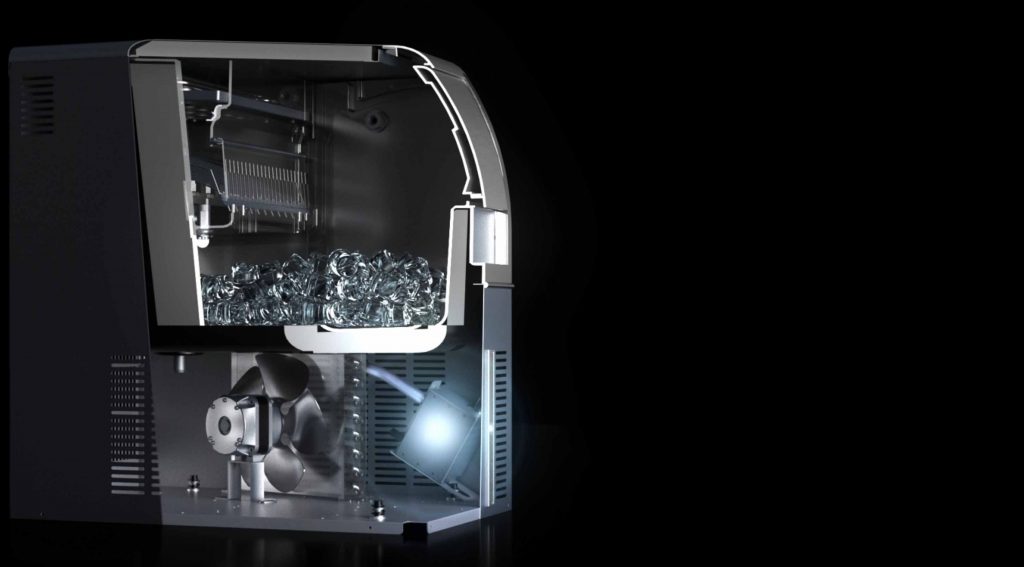

“If guests could see inside [the machine] they would never order ice,” he says. “I’m pretty surprised that most ice machine producers are not talking about what is going on inside the machine. Some producers have more expensive machines that have stainless steel or easily cleanable parts, but many others do not, even though this is a really competitive market.

“The biggest problem is that machines are not clean inside, and that is a major issue when we have a virus like Covid-19,” he adds. “Some manufacturers are trying to improve hygiene, but most are not. They see cleaning a machine as not their job; it is for the users. If I go into a restaurant or bar operated by one of our clients, one of the first things I do is open the ice machine and take a picture. Hygiene is one of the most important things, but you don’t see a lot of development in that area.”

Follett Ice is among the manufacturers that have responded to the need to deliver ice in a sanitary manner. For example, while some ice machines are placed on top of the dispenser, Follett has a system that fills the dispenser through a tube from a machine in the kitchen.

“The sanitation benefit is that there is easier access to the dispenser to clean it as there is no ice machine on top,” notes Bingham. “We have seen a rise in demand for that type of system because of the opportunity for better sanitation. That is the kind of good practice that will stick after the pandemic.

“That said, we develop reliable machines that don’t need a lot of cleaning,” he adds. “One big challenge is water quality. Water going in can have a variety of different chemistries. Manufacturers handle water quality in different ways, but our path is to design a method of isolating and then flushing out the solids using just a small amount of water because water efficiency is as important as energy efficiency.”

The solution relies on measuring the conductivity of the water to assess its purity. Cleaner water is more conductive, so measuring conductivity gives an indication of the total dissolved solids (TDS) it contains. When water freezes, particulate matter is left behind and the ice coming out is low in dissolved solids, but large amounts of scale can be left behind.

Furthermore, calcium, silica or other particulate materials behave differently. The levels of each particulate vary around the world and even in the same location over time, so different filtering and water treatment methods are required before water reaches the ice machine. This is what Follett’s technology measures and manages.

“People clean what they can see – floors, surfaces – but you need to clean inside, and some users don’t even know what the machine looks like on the inside,” notes Hofer. “Ice machines should be cleaned on a regular, scheduled basis to ensure customers are not at risk of contamination. If you are a manufacturer that can sell units on the point of hygiene then you will do well.”

Green ice

Covid has brought hygiene to the top of the agenda, but close behind is the long-term trend towards sustainability. Ice machines are power-hungry pieces of equipment, meaning operators’ costs could rise as the demand for ice increases.

“There has been a number of advancements over the years, some of which have been driven by customers and some by regulation, some by manufacturers seeing a need for more energy-efficient machines,” says Bingham. “There is growing customer desire for environmentally responsible equipment, which means improvements in energy efficiency and changes to refrigerants.

“They are competing requirements because greener refrigerants are not always as energy efficient as what they replace,” he adds. “So, there is a balance to be struck there, as we must ensure there is a gain in energy efficiency. Manufacturers have to understand what is most important, so we deliver what our customers value the most.”

Recent improvements include Hoshizaki’s CycleSaver, an innovative design for its range of KM Edge ice machines that enables the same quantity of ice to be produced in approximately half as many cycles. This leads to significant energy savings, extends the workable life of the machine and minimises maintenance requirements.

Follett also has focus in this area. “Predictive maintenance, getting ahead of failures – that is where the industry is going and we are spending a lot of energy thinking about that,” says Bingham.

Large cubes, small cubes, flaked ice or nugget ice – it is easy to say they are all just frozen water. But there are factors that go into making ice in a way that suits customers, minimizes resource use, preserves health, and benefits an operator’s bottom line. The most successful manufacturers will be those that appreciate the importance of all of those factors.

Jim Banks