Meiko, the specialist for hygiene technology and food waste systems, has been dealing with the challenges customers face in everyday business for quite some time. Foremost among these are the shortage of labour, exploding energy costs, hygiene, which is being driven even further by the pandemic, and the lack of space often found in large kitchens. These challenges come to the focus in all developments of the solution-oriented machine manufacturer. Partially or fully automated solutions that counteract the lack of personnel and work particularly economically are currently in particularly high demand.

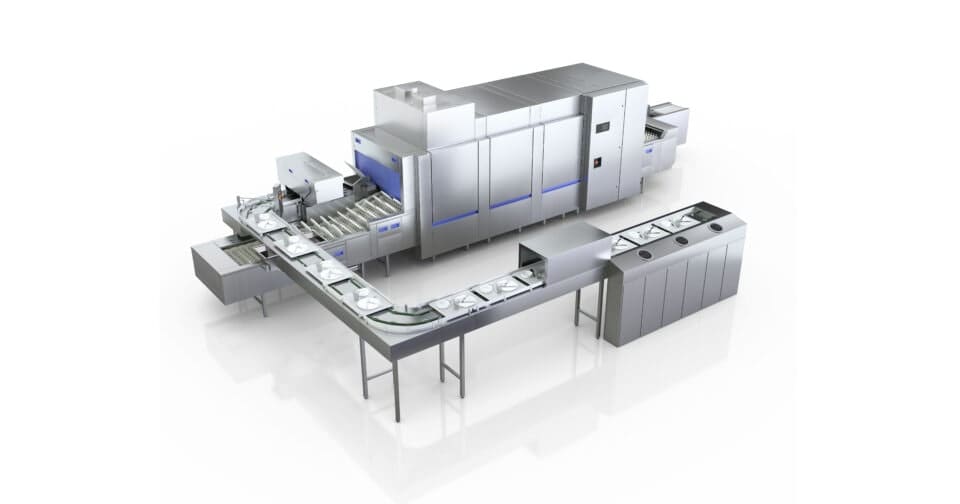

The newly developed Meiko M-iQ Bluefire is an answer to the personnel and cost situation. Meiko has succeeded in washing dishes, cutlery and trays in three lanes in accordance with DIN standards with just one machine. Trays even exceed the DIN standard, with more than two minutes contact time and thus an excellent drying result. The machine has a high level of automation, trays and cutlery are automatically fed into the machine. The dishes are manually fed onto the extremely wide dish track of 640 mm belt slot width (unique on the market). This means that GN containers and EN crates can also be fed crosswise. Technically, two dishwashers (one for dishes, cutlery and one for trays) have been combined. This accommodates the lack of space that is prevalent in large kitchens.

What does this mean in concrete terms in terms of costs, manpower?

Using the example of a completed project in Germany, a conventional semi-automatic belt machine was replaced by a MEIKO M-iQ Bluefire. The result was a total operating cost saving of approximately 94,000 EUR per year. The machine can be operated by 5 instead of 7 persons. Thanks to the high degree of automation, this area is no longer so labour-intensive and the employees are relieved. The Meiko M-iQ BlueFire is designed to run more quietly, emit less vapours into the room and ensure shorter working distances. All in all, a significant improvement in the washing process. The fact that there is only one machine means that the cleaning effort is easy to carry out and manageable.

New on the market and already winning awards:

Such innovative solutions are also looked at closely by experts, especially those who award prizes: MEIKO received the Kitchen Best Product Award 2022 and the Cooking Award 2023 in Gold. The jury was particularly impressed by the enormous added value for customers.

To see the products in action, check out these videos from completed projects:

Two become one at Provinzial in Münster: M-iQ BlueFire – YouTube

Customer: Canteen of the Provinzial Holding AG at Münster / Ville Valtteri Lammi,

Make one out of two – The new MEIKO M-iQ Bluefire at the University Hospital Erlangen – YouTube

Customer: University Hospital at Erlangen

For more information, please visit: www.meiko.info