So far, most of the discussion about artificial intelligence (AI) and Generative Pre-Trained Transformer (GPT) and other generative AI systems has been about how it will impact consultants and designers in their practice: the potential benefits and drawbacks. How AI can support the decision-making process and augment the capability and efficiency of the designers and their designs? My conclusion: currently Generative AI can help the less experienced consultants but not be of so much value to experienced designers in delivering value to their clients.

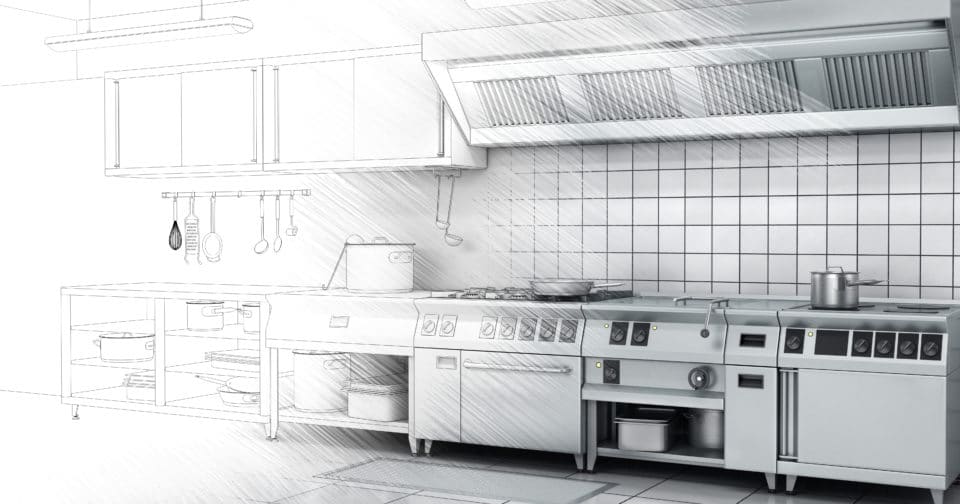

But this has been a bit self-referential; all about us, not about how AI might affect or benefit our clients operations, which is the primary purpose of our business. There certainly has been considerable work by foodservice equipment manufacturers in the operation and programming the functions of their equipment. And even to some extent within industry corporate groups, the potential interoperability of their equipment: ‘The connected kitchen’, with some vague benefits of programming menu’s and maintenance.

But that’s where it comes to an end: a selling benefit. Instead of the chef having multiple CD’s in the bottom drawer of the desk, they now, metaphorically, have only one (in the cloud).

The valid complaint, not only in the foodservice industry, has been that the development of each of these interoperable software systems were siloed, locked in a plethora of domain specific connectivity technologies used in Industrial Internet of Things (IIoT) closed systems between in house brands.

However, the (IT) world does not stand still and considerable work has been done on the “Industrial Internet of Things Connectivity Framework” (IICF). This is a reference architecture that uses gateways to existing connectivity standards that can provide syntactic interoperability; achieved without compromising the fidelity of the functional and non-functional aspects of each domain specific technology. In other words, the individual corporate IP of the system (or equipment) components is protected, including externally through a Common Security Framework (IISF).

Industry 3.0 was made possible by the introduction of computers; it was disruptive to the earlier analogue approach (I2.0) thanks to an entirely new technology. The development of IICF enables the next stage to Industry 4.0 which optimises the computer connectivity and communication to ultimately make decisions without human involvement. A combination of cyber-physical systems, the Internet of Things and the Internet of Systems make Industry 4.0 possible, and the smart kitchen a possibility.

Foodservice Industry 4.0 (FI4.0)

Applying Industry 4.0 to the foodservice industry, the bad news is that the industry is not ready. Very few foodservice operations have even embraced Industry 3.0 (automation) and in many cases not even Industry 2.0 (mass/quantity production). The good news is that by understanding the potential possibilities beyond Industry 3.0, it can give reason to accelerate the adoption of computerisation and automation within existing operations (FI:3.0). In the case of the foodservice industry there is an advantage to being a late adopter; the benefit of seeing over the horizon.

So, what might this FI:4.0 future look like? The first requirement is Machine Learning. More than the capability of remote programming and communication, each relevant item of equipment will be designed to get smarter by collecting data on its operation and using that data to refine and improve the effectiveness of its functionality. Automatically learning by regular re-programming what is required for the next stage and adjusting performance accordingly: recognising set-point anomalies that indicate a need for maintenance: and implementing actions without the need for human intervention or interrogation.

More efficient, productive kitchens

As a result of all equipment getting smarter as they get access to more data, our kitchens are able to become more efficient and productive and less wasteful. Ultimately, it will be the network of all the kitchen equipment digitally connected with one another, creating and sharing information that will result in the true power of Foodservice Industry 4.0. So now we can know why we are making the equipment we use in the kitchen smarter: and that it’s much more than a point of difference and “Nice to Have”.

The foodservice business starts with the customer and ends with the customer. The customer, in one way or another, places an order which gets made, delivered, consumed and paid for. By placing the order, the customer sets in train a predictable series of actions, which in turn have predictable consequences. At the moment an item is ordered, all the relevant digitally linked equipment required to process and finish the order can automatically be engaged and energised (it has been on standby to save energy). The stock of items is reduced, and the minimum stock level is automatically adjusted; and when that is reached an order automatically placed with the supplier.

During the week, supply chain data for the item has indicated a supply issue, the minimal stock level is adjusted automatically so that replacements are ordered sooner to avoid running short. There are many Kitchen and Menu Management systems that achieve much of these benefits and integrate the information required to increase the efficiency of the staffing, supply and ordering system. However they often require manual prompting to maintain relevance and manage exceptions and are not able to integrate with data from the plant or equipment that could impact on the delivery of the service.

Through menu management and staffing systems, the integration of materials input data in the professional foodservice is more advanced than is the production process data retrieved from plant and equipment. The next level will be the integration of external data (such as the impact of weather, supply chains etc) relevant to the reliable material supply. After that the systems will require considerable advances in the machine learning capability of equipment to achieve more than small incremental improvements to make that final jump to Foodservice Industry 4.0.

Industry 4.0 is all about connected machines and systems accumulating a tremendous volume of data that can inform performance and other issues as well as analyse the data to identify patterns and insights that would be impossible for humans to do in a reasonable timeframe. So often we say that a consequence was predictable. Hindsight is looking back on data that has led up to a consequence. With machine learning and analytics in business, the issue of unintended consequences is significantly minimised. Or put another way the benefits greatly maximised. Machine learning uses AI to create a better human experience. But the biggest barrier is cultural: and in almost more than in any other industry, this often applies in the foodservice industry.

To quote Wanyu He, architect and founder XKool Technology: “Rejecting technology won’t make it disappear – only by embracing it can you be involved in controlling it.”

Tim Smallwood FFCSI