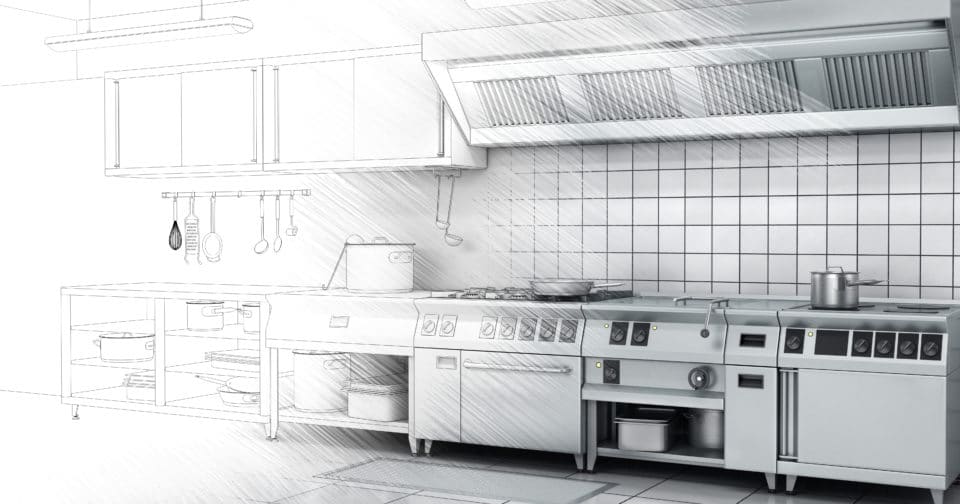

The more efficient the equipment and systems, the more effective the central production kitchen (CPK) will be in delivering on the ambition. But to achieve that will require a complete change in approach and considerable research into the possibilities. It may be that much of the equipment used in the individual operation will not be suitable for a scaled-up production. Just multiplying the number of ovens used in the original kitchen to produce the increased volume, even when being operated over and 8- or 10-hour shift, may make it possible to achieve the volume but at the cost of space, labour and energy.

In the original kitchen, equipment items such as ovens will have been used for a variety of cooking tasks, particularly in the case of combination steaming ovens. In the production kitchen, and item of equipment may be used for the same task all day. To resolve the equipment and systems required, start by ignoring how you are currently producing items.

Before any facilities requirements can be established it is necessary to confirm the logistic solution, particularly the frequency of dispatch to the receiving kitchens and when relevant, the variables in the delivery requirements. The CPK production process will be to the holding storage stage and, from there, the batching for each destination. Batch sizes and delivery frequency will be factors in determining the production scheduling.

The first step in determining equipment requirements will be to analyse each menu item being produced by peak volume through the year to allow for seasonal variations. The peak volume will then be used to break down and schedule a list of items being produced categorised by daily or shift volume and by the steps in the production process. This data will be used to identify the equipment and systems options.

Heavy-duty continuous production

The CPK production will be high in terms of volume per hour by catering standards but by food processing norms where the equipment is designed for production in many thousands of units per hour, it is small. The result is that the availability of automated or semi-automated production equipment scaled for the average CPK can be limited and may take time to source. Conveyor ovens, steamers and fryers have been available for large scale catering (and pizza) production for many years, and may be suitable for some items in the CPK, however they are generally not designed for the heavy-duty continuous production required of the CPK.

Production processes in a CPK are generally semi-automatic where practical, but the input and output will be in batches because that is how ultimately it will be delivered. The production of chilled sauces, stocks or wet dishes that are cooked in a kettle will be the easiest to automate. These items can be pumped hot to a vertical form fill bagging machine and filled/sealed bags dropped on to a conveyor which deposits them in a chill tank or spiral chiller, which then deposits the bagged product into the packing batching cold store. No manual intervention between loading the ingredients into the kettle and sorting the finished bagged items as a continuous flow, labelled ready for dispatch.

Whilst the preparation of ingredients can be done in the CPK it is often worth checking if a food processor using specialise high volume equipment to prepare ingredients at a lower cost is able to provide the ready to cook ingredients. In this case, as with all production inputs, that the supplier is able to provide full ISO22000 HACCP traceability that can be incorporated into the CPK HACCP program. Even with this accreditation it can be prudent to validate through inspection and random testing incoming items. It has to be remembered that with an increase in volume comes an increase in risk, with examples in the past (think hamburger patties) that have resulted not only in human tragedy but also the failure of the business: customer and brand protection at all times must be a guiding principle.

How external storage areas can help

The simplest form of automation that is seldom seen in commercial kitchens, even though able to be inexpensively applied, is the conveyor. Conveyors can be as simple as unpowered roller conveyors or powered belt, slat or roller conveyors depending on what needs to be handled. A solution to moving items from the external storage areas into the clean production kitchen area can be by conveyor to eliminate the need for staff to move between the unclean and clean areas.

A powered conveyor can also be part of an automatic or semi-automatic filling system. The feeding equipment is placed over the conveyor in where it deposits either dry or wet ingredients in sequence, providing for far improved accuracy than manual portioning as well as saving on labour. Loading bowls or food pans on the conveyor and removing them to the next production stage can be manual or automated. However, starting off using manual handing will enable the system to be proofed out and adapted before investing in automated equipment.

This may also, in time, be a means of increasing the production throughput as well as efficiency. It is always worth the time spent on researching food production equipment manufacturers for equipment and systems suitable for the CPK typical volume requirements. An example is a recent development by a major production plant manufacturer of a compact rotary automatic bowl filling and lidding machine with a capacity of over 2,000 units an hour in a space of no more than a square meter; very applicable to a CPK. However, be prepared for costs significantly higher than is usual for foodservice equipment. But the lifecycle cost of ownership (including power, maintenance etc) when offset against the measurable cost of labour saved over 2 or 3 years will determine if the investment is worthwhile whatever the initial outlay.

Frequently the cost of space will be a factor in establishing a CPK, in which case the actual floor space taken by equipment will be a determining factor in the cost of ownership. An example of this is considering batch chilling equipment. Roll in blast chiller(s) will be the immediate assumption, with the number required and capacity based on a 60 – 90-minute cycle chilling. However, the floor space for the number of chillers required can be considerable. An alternative to consider, although at a significantly higher capital cost would be the vacuum chiller which will chill down the same batches in between 15 and 20 minutes, a 4.5 factor space and time efficiency gain.

In selecting equipment, another important factor is the ease and speed of cleaning between batches of different food items. “Clean in Place” (CIP) is a term used in the food and pharmaceutical industry to identify equipment that does not have to be dismantled to be cleaned. It is a built in programmed cycle that enables the changeover with minimal intervention and always worth asking the question if the option is available when considering production equipment.

Planning for maximum flexibility

Having decided to invest in automating the production process, and planning for maximum flexibility, the anticipated lifecycle of the plant will be even more important today than in previous years because of the rate of change and development of upgraded systems. Considering the expected investment lifecycle of at least 10 years it means that the facility has to ensure its viability by selecting the most advanced equipment to start with. Even selecting the most advanced equipment (which could even be superseded by the time the facility is commissioned) it is important to ensure the supplier has the capability of providing system upgrades. Once the production system has been settled down, all bugs resolved, and everything operating smoothly, for many reasons you will start looking for additional efficiency improvements which will involve more than providing more than the essential planned maintenance.

Since 2020 the pace of development of industry IT systems has exploded and the opportunities for applying developments in generative AI and machine learning is growing exponentially. However, the potential to take the Foodservice Industry to Industry 4 level may be a much slower progress, given the starting point is well back in the field when compared with many food industry partners, but not impossible with imagination and commitment.

Tim Smallwood FFCSI