KFC’s supply chain debacle in the UK has dominated headlines for the past week, revealing significant problems with the chain’s new foodservice suppliers DHL, its relationship with Quick Service Logistics (QSL), failed deliveries, supervision issues and temporary store closures. Here management expert and former DHL operations director, Gerry Brown, outlines where things went wrong and the lessons learned.

Mistakes made

According to Brown (pictured), currently chairman of Novaquest Capital Management, a private equity firm focused on life sciences, there are a number of key factors that resulted in KFC’s supply chain failures. He details them below:

1) Only one distribution centre was used by DHL (as opposed to six under previous supplier Bidvest)

Chilled food logistics is complex and time sensitive. The KFC franchises will have been used to placing an order online and the next day they get it. Delivering the goods is not an easy thing to do. Bidvest had been doing it for some time using a number of distribution centres, so if there was a problem with one there were others to supply cover. Having one distribution centre is always risky. You’ve got all your eggs in one basket with no room to manoeuvre, and when you’re talking about ‘just in time’ then that makes it more difficult.

2) The computer systems used were different and provided by a partner – Quick Service Logistics

New systems have to be properly tested, rigorous and working. You have to know they’re functioning properly before you put them into one big distribution centre. The problem was it wasn’t a KFC or DHL system, it was a third party’s, which they weren’t used to.

3) The distributor was not experienced in chilled foods

This is the big one. I used to work as operations director at DHL, so I know they’re a big organisation and good at distribution, but they’re not experts in chilled food. They had problems a few years back distributing to Burger King. So you have to ask on what basis were they selected by KFC? Have KFC got enough capability in terms of logistics expertise and food knowledge on the board to make this decision? I don’t think so.

Proper chilled food distribution is a huge logistical operation that requires thorough management, supervision and expertise.

4) Board and management level mistakes

Lack of experience – KFC didn’t have the required experience of logistics and put too much trust in DHL. They should have had experienced people looking over the suppliers shoulders.

Insufficient due diligence – When I was operations director at DHL and we got a new distribution contract, we would meet with the distribution director of the company and plan for failure. We would say what are the 20 things that could go wrong, such as computer systems shutting down, people not turning up for work, an accident on the M6, and have a contingency plan. That clearly didn’t happen in this case.

Cost cutting – They took a cost effective approach. But what you have to do with the start of a new operation is spend a lot of money upfront – employ people weeks in advance, do practice runs at the depot, train the drivers, make sure the computer systems are working smoothly. All of that costs money, which I don’t think was spent.

No contingency planning – DHL should have had a back-up facility – they have operations all over the country. They could also have done a deal with Bidvest to stagger the distribution. Say “we know you lost the contract, but it’s revenue for you, if we stagger this”. That didn’t happen.

Lack of health & safety safeguards – Apparently Rugby Council were not even informed of the food storage plans at the DHL depot. These are basic regulatory requirements. But if they’re not used to dealing with chilled food they wouldn’t necessarily know, or even have thought, about this.

Non executive director (NED) absence – where were the experienced independents to set the board straight?

Lessons learned

1) Select your outsourcing partner carefully

If you can’t find a good outsourced logistics partner with proven experience in the field then you shouldn’t outsource. This is a specialist field, so do your homework.

2) Make a plan

Ask for a detailed presentation by the distributor’s divisional manager responsible. I’ll put money on it that this didn’t happen with KFC. Logistics is such an important part of the chilled food industry. There should always be a plan, including the ‘what if’ scenarios. It sounds basic, but in my experience, having served on 11 boards, it doesn’t happen enough times.

3) Manage your new logistics partner carefully

Within the corporation – whether it’s on the board, non-executives or consultants – you have to have expertise about supply chain and logistics in the chilled food sector, including digital informatics. It is a core competency, as important as finance, marketing and HR. Don’t make the mistake that because you’re outsourcing, you don’t need that competence.

4) New supplier needs to be confident in the area

DHL has proven expertise in managing the supply chain for many sectors, including the automotive, petroleum and retail logistics industries, but that doesn’t mean it’s going to be easy to transfer to chilled foods. If you are any company in the food area now and DHL are broking for a contract, it’s going to be hard to look beyond the fiasco of KFC.

With supply chain in chilled food you’ve got strict rules because food can go off in a matter of hours. So you have to have management, pickers, drivers, administration staff, IT guys, everyone understand this because it influences their job. If you’re a driver, for example, you have to make sure you’ve got a recorder on the vehicle that tracks the temperature control every hour. Equally, you need a computer system that has been tested in chilled food distribution, and staff used to working together. It’s a huge operation delivering to 900 stores up and down the country. The human aspect is vital. When you’re choosing a supplier you need to have that detailed operational specific knowledge.

Fallout and reaction

KFC

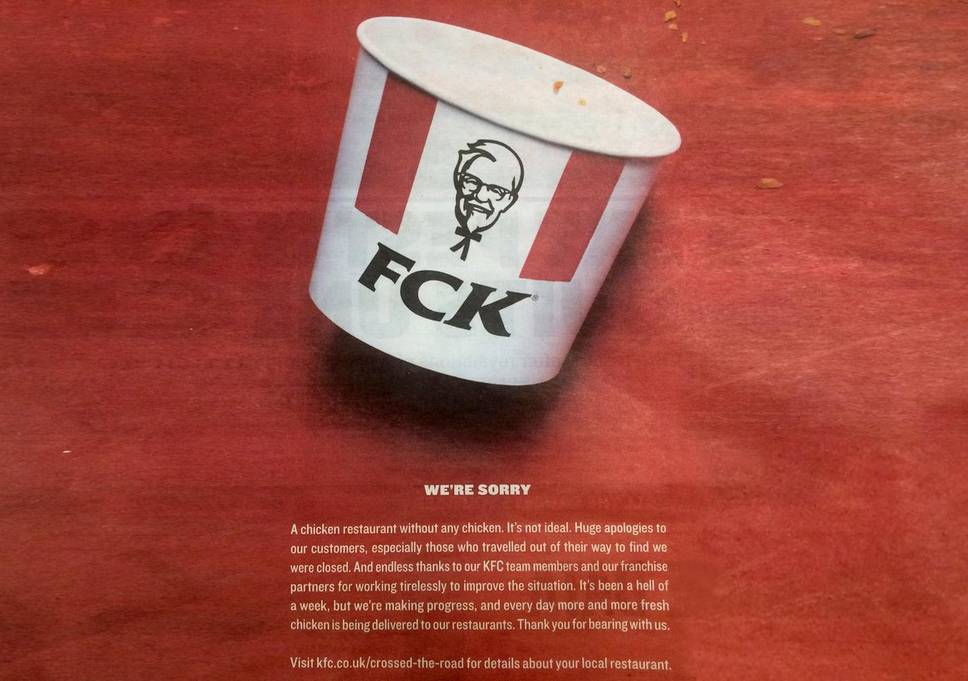

They’ve actually done remarkably well in their marketing, especially their humorous ad campaign with the empty bucket of chicken plastered with the re-arranged letters FCK. The man on the street has mostly accepted the humour and the apology from KFC. So they’ve not done a bad job. But from a business point of view, it’s been a disaster.

DHL

DHL ought to apologise, but not in the way KFC have done – they’re not the same sort of brand. They should say something like: “This is a big distribution centre and when it works it will be very efficient and ground-breaking, but making it work doesn’t happen over night. Secondly, we are using some of the most sophisticated IT systems in the world, which when working well will bring great benefits. Thirdly, we have cost constraints which meant this was going to be difficult, but we’re doing our best.” But we’ve heard nothing. They’re keeping their heads down, which is a big mistake.

Food waste

All the chickens were delivered into the central warehouse and suddenly they’ve got to get rid of them. That’s easier said than done. Most of them are going to end up in landfill. Imagine the PR disaster that is for KFC, in terms of sustainability.

Chris Evans

The Independent Director: The Non-Executive Director’s Guide to Effective Board Presence

by Gerry Brown is available in hardback from Palgrave Macmillan (£29.99)