“My life has changed completely. Waste is worth something if people can put their minds into it” – Stanley Mangoegape, depot manager, REDISA, South African NPC

Most of our economy is linear – it works in a straight line, no matter how efficient you make it. If you make an oven with less material; if you make it more efficient and use less energy, you are still using stuff. You are consuming new material.

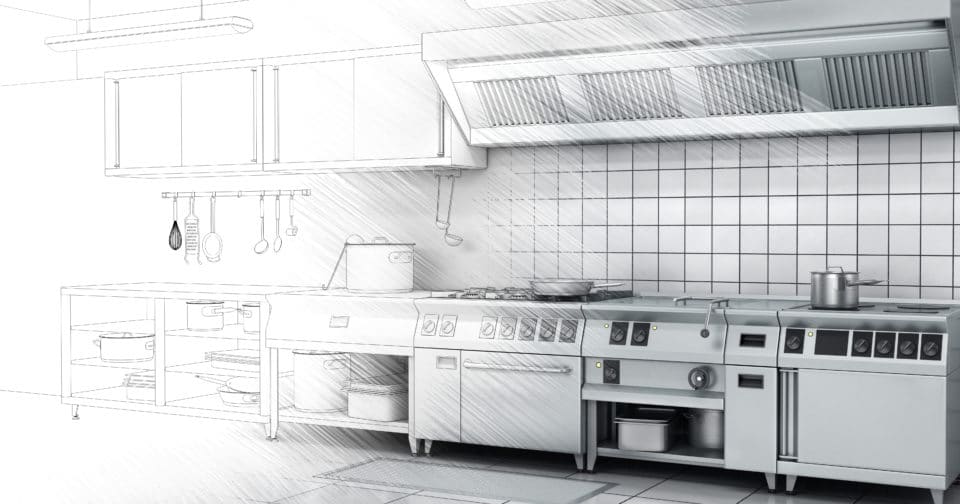

In a circular economy the oven is designed from the outset so that the item comes back into the production system at the end of its useful life with the materials and components recovered or the item is reconfigured to be used in another way, a second life, rather than just being disposed of as waste.

The designer’s role (and here management advisory services (MAS) system “designers” are included) in the first step is to design out waste and pollution and then to develop and apply natural regenerative systems, such as compostable plastics, paper, cotton, human and agricultural waste so that it can be fed back into the natural system to regenerate.

All in the brief

Designing out waste and pollution can be both physical and operational. For the kitchen designer, the brief will normally be for a facility to deliver so much food to so many people in so much time using a given a finite level of resources. What is generally missing in the brief is any direction on how to make the facilities continuously upgradeable and then what should happen to the individual components at the end of their usable life.

In the same way the client brief for the operation of the facility is focused on meal production, quality and performance but seldom on any target for the elimination of waste or the management of consumables and packaging materials.

Many small steps are being taken by individuals and organisations to this end, for example: reusable coffee cups and recyclable drink containers. But, to be effective, whole economies will have to change and now could be the time to motivate that change in the foodservice and hospitality industry, which is the hardest hit in the current circumstances. To get through and survive, individual businesses will have to be capable of doing more with less: less facilities; less staff and less materials.

Whilst in certain sectors of the foodservice industry, mainly institutional, facilities are expected to last longer than almost in any other industry: certainly decades, at the retail level however, there is continuous change and upgrade, which often results in the generation of a considerable amount of waste. In the future this cannot be afforded and if the design of the facility and the materials involved can be recovered or given a second or third life, there will be an economic as well as environmental benefit.

Waste and pollution are natural by-products of the catering industry, but only because to do anything about it is seldom on the list of priorities compared with all the other pressures involved in running a foodservice business. But in the new normal, having to do more with less in order to survive the additional costs and limits placed on businesses, managing waste and therefore pollution can be a significant cost saving as well as environmental benefit.

Good value, good business

In the case of the ingredients and consumables, producing only as much as is required and not overloading or filling the serve so that it looks generous and “good value” – but then half is returned or thrown out – is not good business.

The additional cost of handling, storing, preparing, plating and serving and then the cost of disposing of all the waste can be avoided for the profitable benefit of the business as well as the environment. In the case of the materials used in the foodservice production process there are equipment and systems that can be used to manage and even eliminate the pollution that gets fed into the environment from the operation of commercial kitchens.

Replacing cleaning and sanitising chemicals with environmentally friendly alternatives using equipment such as ROX electrolysed water systems and, instead of sending food waste to land fill, using dehydration to convert food waste to a nutrient rich soil enhancer using equipment such as Gaia are two such cost effective technologies with a valuable financial as well as environmental payback on their investment.

Many companies are now using recyclable packaging for their product, but all too often they are not effectively sorted at the point of removal from the kitchen. It is possible for designers to develop systems and facilities that will make it easier for the operator’s staff to dispose properly and safe time and money in the process.

A new normal is already underway with the development and acceptance by operators of the dark or shared central kitchens which make a more efficient use of capital and human resources. The designer of these facilities now has to make sure that they maximise the efficient use of the material resources through the selection of equipment on whole of life criteria and the operating systems through the end-to-end management of consumable resources.

Effective process

In some countries around the world, equipment and machinery is required to be designed so that a certain percentage of the materials involved can be recycled and the manufacturer required to take back redundant equipment for recycling. There can be no argument that this is a good initiative, but in this global economy it would make no sense to ship the old oven from one side of the world to the original manufacturer on the other side of the world for recycling.

In addition to a reliable equipment supply chain for ongoing service and maintenance, the new normal will be that specifiers and buyers insist there is an effective process for the final disposal of equipment wherever they are located for the benefit of the owner as the final link in the chain. Manufacturers, suppliers and users will find that all these circular economy strategies have a positive value that should encourage their acceptance and uptake.

There are many fine organisations working on developing downstream systems for cleaning up waste in the environment. What is needed is for innovation in the design of upstream facilities and systems that give a visible value to the downstream waste to encourage the new normal circular economy and replace the everything disposable culture with a healthy, ‘everything reusable’ culture, as well as the elimination of toxins going into our environment.

Tim Smallwood FFCSI