When we discuss automation and robotics, we’re talking about their relevance for the manufacturing industries, aren’t we? Not necessarily. It depends on what you mean by the words. ‘Automation’ typically refers to technology applications where human input is minimized (IBM). ‘Robotics’ refers to the use of machines to perform tasks done traditionally by humans (Britannica) usually to replace tasks referred to as “the four ‘Ds”: dirty, dangerous, dear (expensive) and dull (or demeaning).

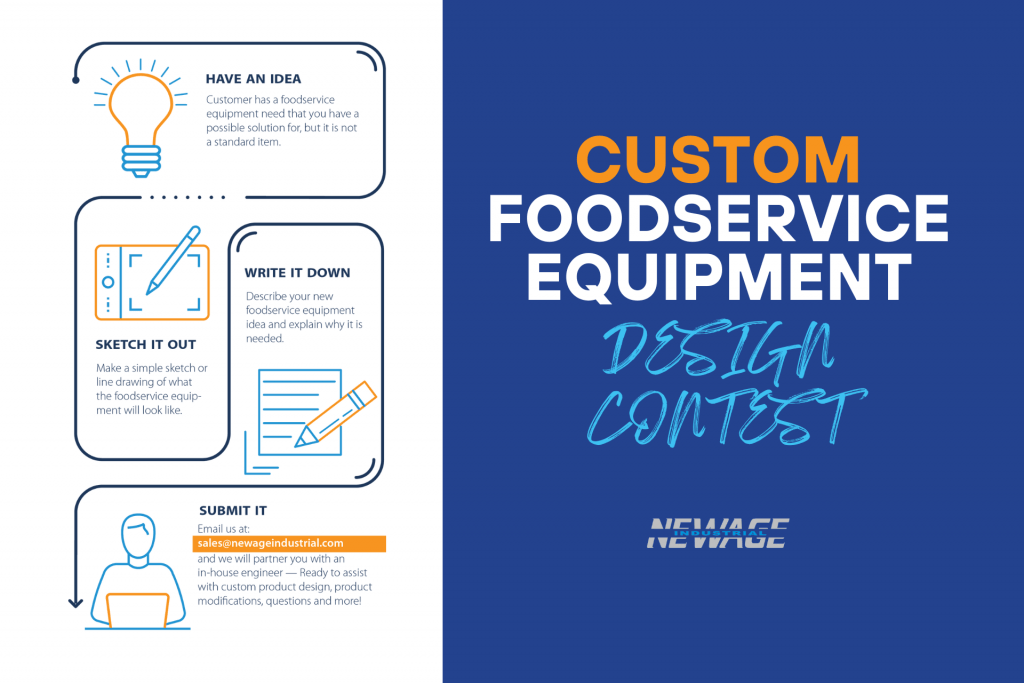

In fact, these aspects of technology, by these definitions, are already being applied in the foodservice industry. Currently the introduction and application has almost always been driven by operators and their suppliers rather than their consultants. Now the question is, where can they take us in the future, and how can the foodservice consultant assist in their development?

Automation in the foodservice industry has already gone beyond creating simple efficiencies and cutting costs through the use of data. It can be seen enhancing employee productivity by using that data to directly link the point-of-sale order to the beverage dispensing machine and the streamlining of operations by automatically sorting and bagging cutlery after washing or the transport of meal carts through a hospital using robotic shuttles. These are all examples that have evolved since even before the turn of the century to applying automation to robotic machines that replace a human activity to replace one of “The four Ds”.

Fully automatic cocktail mixing stations seemed more a case of demonstrating the possibilities than a genuine attempt to replace an effective bartender with a machine to replace a dirty, dangerous, dear, or dull job; but it is still an effective demonstration of the possibilities of imagination.

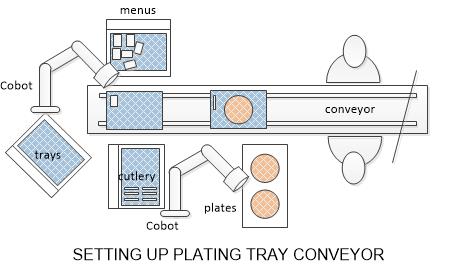

Repetitive and dull jobs exist in a number of foodservice industry segments including healthcare, industry and even banqueting. They all have instances where repetitive tasks occur in number and frequency that could benefit from a level of automation. Not to replace existing jobs but to free up the individual for a more fulfilling activity. Although sometimes the introduction of robotics can help overcome the lack of availability of staff willing to turn up regularly to undertake such uninteresting activity.

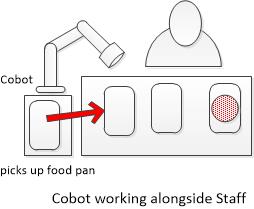

Rise of the Cobot

However, using an industrial robot in a protective cage to fully replace the employee might be considered a step too far and not practical in a people-based industry. However the development of a whole new field of robotics in the past decade does give the possibility of taking automation to a whole new level in the commercial kitchen. Here I’m not thinking of a humanoid machine strutting around the kitchen wielding a knife, I’m talking about Cobots.

A Cobot is a collaborative robot that can operate safely in conjunction with, and in close proximity to, humans to perform equivalent tasks. They are intentionally built to physically interact with humans in a shared workspace. In the same way as augmented intelligence is applied in the information technology world, Cobots are able to augment and enhance human capabilities with super strength, precision, and data capabilities so they can provide more value to the organization.

Whilst seriously ‘Dirty’ and ‘Dangerous’ tasks are not generally found in commercial kitchen operations, ‘Dear’ and ‘Dull’ frequently are and often go together in a range of industry segments that could take advantage of the Cobots ability to be programmed to replicate human actions.

Cobots are made in a range of sizes and capacities that can be fixed, table mounted or on carts that can be moved around the workspace. A typical range of table mounted units (UR) range from the smallest weighing 11kg with a reach of 500mm and payload of 3kg up with others capable of handling up to 16gms and reaching 1300mm. As with all Cobots they are capable of 360-degree rotation on all joints and infinite rotation all with an accuracy of ±0.03mm. They can be quickly and easily “taught” by showing or programming and be fitted with an infinite range of adaptors or tools depending on the task required: and even programmed to change their own tools as part of a task.

The “training” of a cobot can be as simple as basically showing it the way, but certainly external programming expertise will need to be available for any changes in requirement. The cobot can be programmed with a number of different tasks which may require switching over during the day, plugging in different tools to get maximum benefit from the investment. However in the case of a hospital foodservice where 800 meals are plated three times a day the unit(s) would be working almost continuously. The introduction of robots into the staff workspace will require gaining the confidence of the staff, however there would be no need to specifically upskill existing food handling employees to work alongside them: give each cobot a name, they soon become part of the team.

Unlike other industries, there are none of the traditional added cost associated with robot programming, set-up and dedicated shielded work cells, meaning the average payback on investment could even be well under 12 months.

Automating the kitchen

One basic area of automation seldom used in commercial kitchens, but which could be used to improve productivity and occupational safety, is the use of conveyors. Simple, flexible, and cost effective: powered or unpowered, they can be used to avoid repetitive lifting and carrying between work areas. But the recognition of the benefit of their use and their application has to be designed into the facility from the very beginning of the design process. It is too often impossible to introduce conveyors as an effective afterthought.

One familiar conveyor in a foodservice, is the Rotation Sushi conveyor which evolved into the familiar pattern in the 1990’s: as much as a selling feature as an efficiency measure. Another familiar application are the conveyors used in the dishwash area and hospital plating rooms. Less often seen are conveyors used for the storage and handling of pallets in the storage areas of large facilities but are seldom considered as a means of transfer from one workstation to the next withing the kitchen food preparation areas.

A potential application of conveyors could be in overcoming issues requiring the separation between the clean kitchen food preparation and handling area and potentially contaminated external areas. Generally supplies for the kitchen are manually transferred across the barrier between the two areas with the employee having to put on hat and gloves and hand wash every time moving between one area and the other: although frequently through necessity or convenience not fulfilling the full safety protocols.

If a conveyor were to be used between the two work areas to transfer supplies, thus avoiding the necessity for staff movement, it is not just an efficiency measure but also a food safety benefit. In this case the conveyor may not necessarily be a set of rollers or a belt, it could also be an overhead system for moving handling carts. As with all these concepts, the possibilities are endless if we are open to them.

The issue of cost will always be seen as an issue, however by exploring other industry conveying system manufacturers, particularly those supplying the garment industry where cost is a significant issue, the limited requirement for a commercial kitchen compared with a manufacturing or distribution business, means that the implementation should be achievable cost effectively, but would require considerable interaction between the client, robotics specialist, system integrator and the foodservice consultant during the early stages of concept development.

The first step is for the foodservice consultant to imagine the possibilities and tell the client the story. But remember Bill Gates’ advice that, “Automation applied to an inefficient operation will magnify the inefficiency.”

Tim Smallwood FFCSI