Foodservice has always been affected by the ebb and flow of cultural change, but current scale and speed are requiring operational change at an unprecedented pace. From smaller footprints and off-premise dining to delivery kitchens and ventless solutions, here are a few ways that Kitchens To Go built by Carlin is supporting both commercial and non-commercial foodservice operators to remain on-point and ahead of the curve.

Solutions To Go™

Kitchens To Go® (KTG) provides – for lease or purchase – flexible mobile, modular and containerized commercial kitchen solutions. For 40 years, KTG has been a trusted source supplying innovative foodservice facility solutions that help operators not only maintain business continuity, but also stay at the strategic cutting edge to best serve their customers.

KTG’s Modular Kitchens provide maximum flexibility with relocatable features for both temporary use and permanent applications. Perfect for ghost kitchens, modular units are scalable, with interchangeable components, and a cost-effective solution to maximize space for cooking, preparation, service, and storage.

Mobile units from KTG are a relocatable, rapidly deployable, on-the-go option and serve everything from one-time special events to daily operations. Our fleet contains units of varying size, utility options, and equipment to best address an operator’s unique challenges.

Our containerized kitchens are high cube 40’ x 8’ units with high volume production capacity that can easily connect to create commercial kitchen complexes. The KTG PAC® Kitchen can be placed and operational quickly.

Smaller footprints

The foodservice industry has consistently evolved towards smaller footprints for as long as cooking technology has allowed. And, with the acceleration of existing trends throughout 2020, operations are more rapidly taking advantage of the real estate savings, improved efficiency and labor cost savings that a smaller footprint provides.

By taking advantage of flexible mobile and modular facilities in conjunction with multi-use foodservice technologies, operations that take the time to right-size square footage to their specific needs (instead of allowing available square footage to determine their operational footprint) quickly gain a competitive edge not possible before.

Green technology

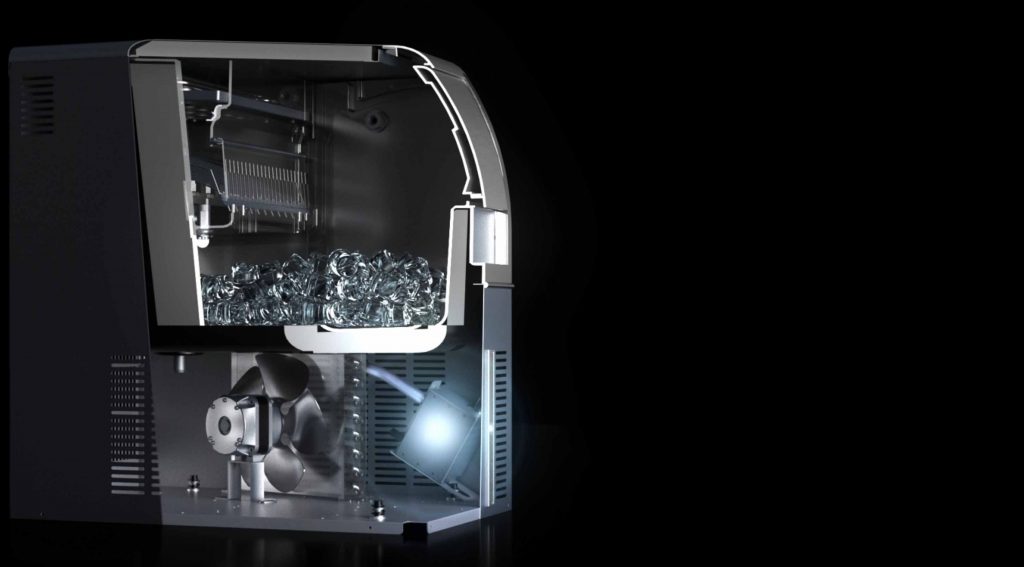

New green and ventless technologies provide a host of advantages that more antiquated equipment simply can’t emulate. And when utilized with mobile, modular and containerized solutions, the flexibility of a foodservice operation becomes virtually limitless.

By utilizing electric, ventless equipment, the need for a hood (along with the risks, operational costs and insurance liabilities that come bundled with it) is eliminated. Energy costs can be reduced from 30-70%, air quality is dramatically increased, water and oil waste are eliminated, as are unpleasant cooking odors. The limitations that have kept operators from establishing serving locations in non-traditional areas are easily overcome with new, flexible strategies from KTG.

PopMarts™

PopMarts™ are custom containerized units that can be placed in strategic locations to create outposts to pull customers away from more dense locations, capture additional foot traffic or reinforce underserved areas. They can be everything from convenience stores or grocery concepts to pick-up stations for prepackaged meals.

With PopMarts™, operators gain the ability to create a configuration and appearance that best integrates with their ongoing strategies. Each unit comes preloaded with equipment, so it’s ready for business the moment it’s placed and stocked. Each unit can be prewired to be integrated with an existing POS system or contactless mobile payment solution.

A superior alternative to phased construction

A phased approach to construction projects has become a widely adopted strategy to allow foodservice operations to continue functioning during an extended renovation or construction project. However, phased construction can extend completion two to three times longer than without phasing, which unnecessarily inflates labor costs, increases safety risks, and is more likely to cause construction fatigue for both employees and customers.

More importantly, phasing a construction project disrupts a foodservice operation’s routine, which inevitably can increase inefficiency, decrease productivity and performance and increase labor costs.

Utilizing mobile, modular or containerized kitchen solutions to replicate an operation’s facilities on-site is a superior alternative to phasing, shortening the time of completion and eliminating the associated risks and costs.

Partner with Kitchens To Go®

KTG’s service, creativity and quality has been recognized by some of the world’s largest organizations and brands both in the United States and 27 other countries. Our experience and innovative solutions can help operators capitalize on the latest and greatest strategies to tackle unique challenges and best serve their customer base. From planned to unplanned situations, KTG’s flexible, customized temporary or permanent solutions will keep you cooking!

Further details:

For additional information about how KTG can help keep you cooking, please visit our site!