As restaurants start to reopen at reduced capacities due to the pandemic and in the absence of clear guidelines, what interventions should be to keep considered to keep customers and employees as safe as possible?

It is well documented that aerosolized virus can spread through a cough or sneeze from an infected person. The accepted distance between people is 6ft, to minimize the risk of contamination. The size of the particulate containing the virus has an impact on how far it will travel and for how long. Temperature and humidity also play a role. Depending on particle size, the contaminant will settle on surfaces. Table spacing and face masks have become part of our daily existence. These measures, along with increase handwashing work to reduce the possibility of contracting the virus.

Extensive research

Healthcare facilities have had established criteria for ventilation design to mitigate airborne transmission of infectious diseases. Organizations like the CDC and ASHRAE are working on guidelines to assist foodservice operators in the same manner.

Halton Health Segment has done extensive research in this area. Halton Health specializes in Isolation and Operating Room ventilation systems. Halton Foodservice is sharing this knowledge to provide proven technology for deployment in the foodservice environment.

These product-based solutions developed by Halton will augment other mediation methods such as social distancing, respiratory masks, and updated sanitation practices along with human behavior changes (thorough washing of your hands, not touching your face).

Factors that influence the spread of a virus indoors include:

- Outdoor ventilation rates

- Type of air distribution method used

- Occupancy related ventilation requirements, higher ventilation rates for higher occupancy

- Treatment of recirculating air

- Treatment of surfaces during unoccupied periods

- Automatic adjustment of ventilation rates

- Monitoring of indoor environmental quality

Minimizing viral spread

UVGI (Ultraviolet light germicidal irradiation) has a long history as a tool for minimizing viral spread. According to NIOSH (the National Institute for Occupational Safety and Health) studies, UV-C in the 254 nm wavelength is the most effective against a virus. Importantly it produces virtually no ozone. Different wavelengths produce much higher levels of ozone, which are a known respiratory irritant and, at higher levels of concentration, can be toxic.

A common misconception is that UVGI kills the virus. It damages its DNA (its genetic code) and its RNA (its genetic code to reproduce) so that it is unable to replicate.

Halton has introduced a line of Halton SafeGuard UVGI products to treat recirculated air and fomite contamination.

A UVGI self-contained return air grille can be easily retrofitted or supplied for new construction. Attempts at integrating UV-C bulbs in to supply or return ducts can be problematic. It is essential that the appropriate velocity across the lamps is controlled to ensure proper dwell time.

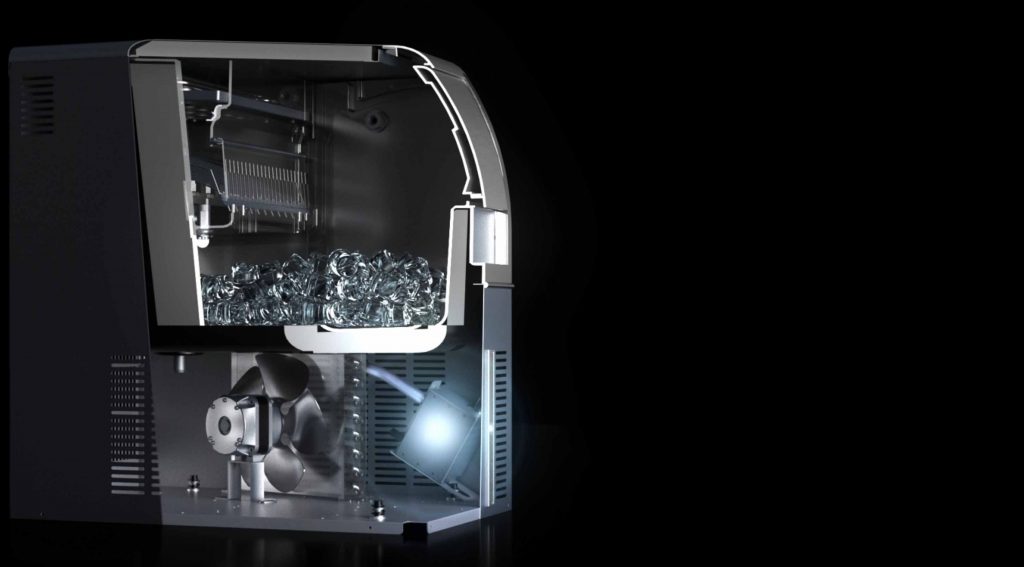

A mobile filtration UVGI device can be brought into any space and used. The number of air changes through the unit can be calculated to determine the effective operating time. This unit would be used during or occupied or unoccupied periods.

For Fomite control (contaminants on surfaces), the UVGI overhead light can be used. These fixtures would operate during unoccupied periods. The sensors would determine when it is safe to operate to avoid exposure to UV radiation.

These products are used in conjunction with other remediation efforts such as sanitizing requirements (wiping down surfaces, face masks, social distancing, etc.) that work to reduce the likelihood of spreading the virus or contagion.

Further details:

From the design concept, Halton is prepared to meet with your design team, contractors, and tenants to review the system and its capabilities.

Find out more about Halton’s UVGI SafeGuard solutions, here.