For years, steam tables have been the go-to hot food well technology. While steam tables keep food hot, they also continue the cooking process by boiling water at 212°F (100°C) to create steam.

This method of heat transfer often results in burnt edges, dried out meat, shorter holding times and increased food waste. Not to mention, steam tables pose space limitations with the need for additional water hookups and filtration systems, depending on the operation’s water quality.

Why choose a waterless food well?

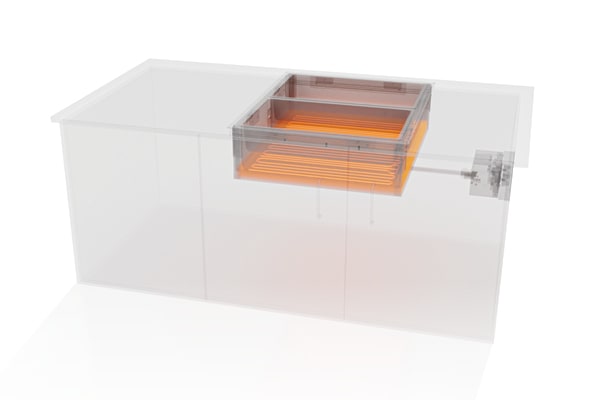

Not all waterless wells are created equal. Some dry wells use harsh heating elements underneath the pan, such as fans. To heat the entire pan, these elements need to get extremely hot, which can easily burn the food at the bottom. On the other hand, there are wells where radiant heat surrounds the food, so it doesn’t need to be as hot or use a fan to get the job done.

Here are the top five benefits to using waterless food wells with radiant heat:

1. Space and operation savings

With Alto-Shaam’s waterless food wells, operators can maximize space without the need for plumbing. Waterless food wells are able to be dropped into any surface—allowing operators to take advantage of extra storage space beneath the countertop. Waterless food wells provide thousands in savings on plumbing work and are energy-efficient. Installation takes fewer steps, allowing operators to plug and play.

2. Lower maintenance costs

Waterless wells require no maintenance or installation costs associated with plumbing and water. Steam tables need to be descaled if a water filtration system is not in place, which adds an additional expense for operators. And if the steam table is dried up, the well can be scorched to the point of needing replacement.

3. Improved food quality

During busy service, it’s easy to forget to refill steam tables. Once low on water, the food will heat unevenly, and food quality suffers. More recent dry well solutions pose similar food quality challenges by using harsh heating sources, such as fans that can evaporate the moisture out of the food. With Halo Heat® technology, waterless food wells provide a gentle, radiant heating source evenly around the pan. Operators can set it and forget it—knowing that their foods’ natural moisture and overall quality is being maintained.

4. Safer work environment

Burns caused by hot liquid and steam are the most common injuries in the kitchen. Scald burns can be serious and life threatening. With waterless hot food wells, employees no longer need to refill or drain scalding water.

5. Safer food

Surrounding food with thermal cabling, Alto-Shaam’s waterless food wells produce more consistent holding temperatures than harsher heating sources. When employees refill steam tables with a new batch of water, the temperature can drop quickly and take a long time to recover. This increases the risk of food falling within the “danger zone,” whereas a waterless well provides a stable heat sources.

Further details:

To learn more about Alto-Shaam’s innovative waterless hot food wells, visit Alto-Shaam’s website.