Although not always recognised as such, ice is actually a food and the ice maker that makes it is food production machine which means that, as well as functionality, hygiene is crucially important as poorly made, stored or handled ice can potentially become a source of food poisoning. After all, the ice contained in the ice bin is a basic foodstuff in its own right, held in a non-refrigerated vessel.

Bad practice

The most common form of ice contamination occurs after the ice has been manufactured. Dirty, unsanitised ice scoops filling a rarely cleaned ice bucket placed on top of a bar top for customers to help themselves leaves much to be desired. Few of us would eat any food that had been through such handling process, yet the deceptively cool, clean appearance of ice diverts our attention from the micro-organisms it can so easily harbour.

Another dangerous practice which is not uncommon amongst people who are scrupulous in every other area of good hygiene, is to use the ice bin as a secondary ‘fridge’ storing bottles and even food – and here it is only education that will improve matters. These areas can, of course, be rectified by following proper procedures, but contamination can also occur within the ice maker itself and this can be caused by poor hygienic maintenance and lack of servicing.

Machine design

The only potential sources of danger at the ice manufacturing stage are air and water and it is therefore imperative to protect as far a possible against the harmful effects of both.

The siting of an ice maker is important. Too often they are slotted into any available space – typically damp cellars or other unventilated areas which are where the environment is at its poorest and aero bacteria are most profound. If this is the only option it is important to ensure that the ice maker has a tightly fitting door, rendering it airtight.

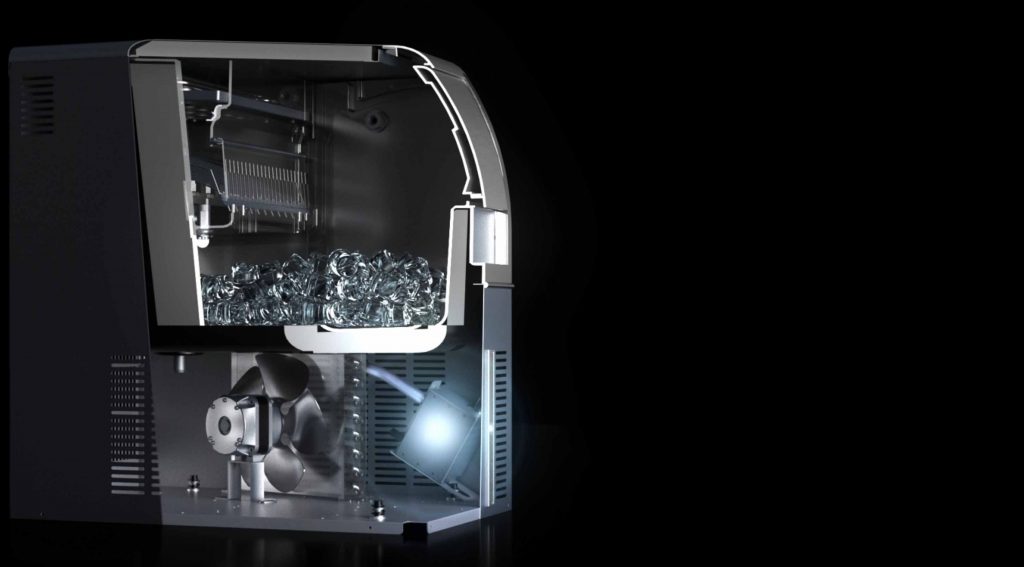

Hoshizaki IM and FM Self-contained machines are uniquely fitted with high density foam injected stainless steel doors, complete with a gasket, to ensure the tightest fit on all four sides.

Without good insulation free bacterial growth can develop in ice storage bins. This manifests itself as a slimy deposit, which, unfortunately, is usually incorporated into the ice bin contents because of the abrasive action of the cubes as ice is collected.

Water is already pre-treated with chlorine to reduce bacteria levels, but water that is held in an ice machine for any time can become dangerous. Although no machines re-use melted ice any more, old water can become trapped in certain machines, providing the right conditions for bacterial growth to appear.

To prevent the possibility of this occurring, Hoshizaki’s IM ice makers are pre-programmed with a unique, automatic rinse and flush which operates after every cycle to ensure all old water is removed and that the new cubes are made from completely fresh water. Also, Hoshizaki machines make ice using an advanced closed cell jet system which, because it is a very precise method, has the advantage of reducing humidity in the machine.

So what can conscientious bartenders do?

Thorough day to day housekeeping and regular maintenance, in combination with a high quality machine, are the most important factors. Reputable manufacturers will have ensured that their machines are as refined as possible and that their dealers and distributors are well informed in the installation, care and servicing requirements necessary to maintaining the highest quality.

The basic guidelines according to Hoshizaki, the world’s leading manufacturer of ice makers, are as follows:

Purchasing

- Select a machine with a tight fitting door compete with a gasket or seal.

- Look for an ergonomically designed ice bin with radiused or rounded corners and with all areas visible and accessible.

- Avoid any machine that has interior joins, cracks or crevices in the ice bin.

- Look for a machine offering a rinse and flush cycle between each ice cycle, thus helping to eliminate water residues.

- Demand a substantial warranty. If a manufacturer is confident in a machine’s quality, this will be provided automatically.

Maintenance

- Ensure all staff are aware of the dangers of contamination and understand how to prevent it.

- Empty the ice bin completely at least once every week to clean and sanitise with a proprietary cleaning fluid such as Milton and rinsed thoroughly.

- Ensure all objects in touch with the ice – such as scoops, tongs and buckets – are also treated.

- Move ice storage vessels away from customer reach.

- Keep regular checks to make sure the machine is in good condition – especially the door, as broken or loose fitting doors are one of the most common faults to occur on ice makers.

Hoshizaki’s IM range is unique and designed with hygiene as a priority. The plastic water plate is automatically rinsed after every cycle ensuring that each ice cube is absolutely clear and free from contaminants. Fresh water is then used for the next cycle. IM machines also feature easy-access condensers air filters making cleaning a simple process and also maximising performance.

The IM range produces exceptionally hard, crystal clear ice – ideal for keeping drinks cooler for longer while the newly launched Emerald Class IM range has even more benefits in that it uses natural hydrocarbon as a refrigerant which helps the environment while dramatically reducing energy bills.

Further information:

Andy Norton. Hoshizaki UK. 2 The Technology Centre. London Road, Swanley BR8 7AG

Tel: 0845 456 0585 Web: www.hoshizaki-europe.com Email: uksales@hoshizaki.co.uk